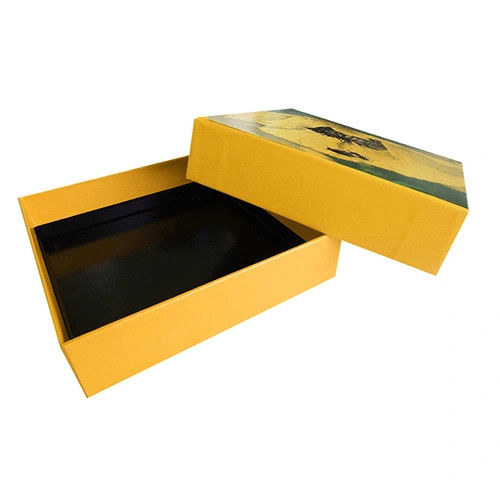

Visual Positioning Machine For Fositioning the Premium Gift Box

high precision

A series of LY-485 products, The parts of Feida feeding, gluing and conveyor belt use independent servo drive. The positioning part adopts YAMAHA robot arm, and camera to visually position the inner box, which can realize high accuracy in the rigid box, bookcase , drawer box, irregular shape boxes. It is suitable for a variety of high-quality gift box which need gluing ,like phone box, cosmetic box, Jewelry box, watch box, wine box, cigarette box, etc.

1. It adopts high speed automatic paper feeding system, which is controlled pneumatically, and its structures simple and reasonable.

2. New designed copper scraper cooperates with the rubber more compactly, effectively avoiding paper winding, and the copper scraper is more durable.

3. Paper feeding and positioning system adopts imported high precision photoelectric control device to make the paper and cardboard location more accurate.

4. It adopts PLC control, simple operation, the troubles are displayed directly on the HMI which helps the operator easily solve the problem.

Feeder

1 . Feeder control by servo motor

2. Paper-feed-in overturn function

3. Big diameter pneumatic vacuum control valves

4. The rubber pressure roller for the feeding-in paper

5. Antistatic platform for paper

6. The automatic lifting function for feeding stack

7. Feeding stack auto stop when top paper in position Feeder control by servo motor

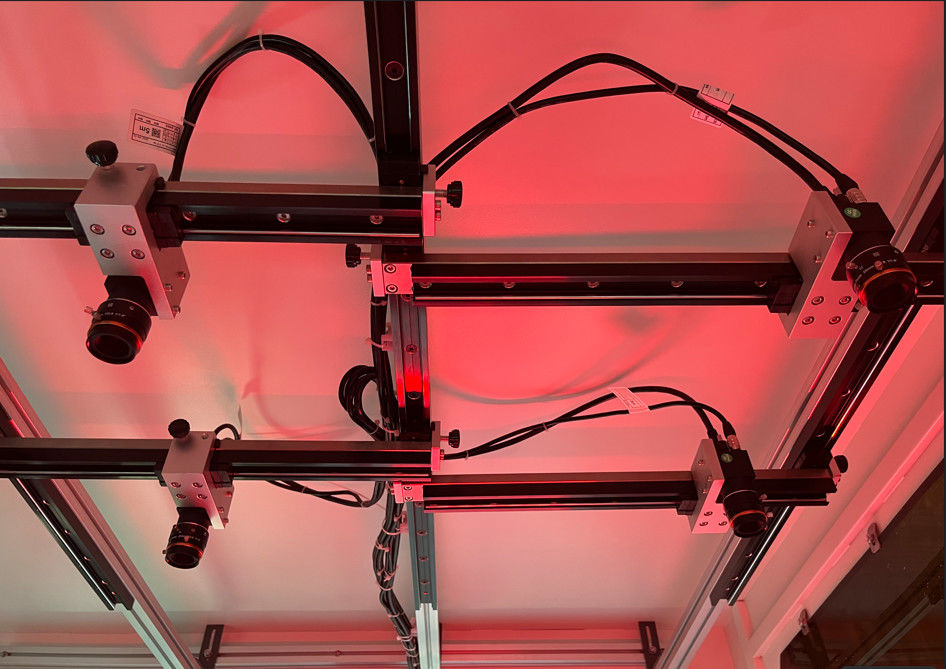

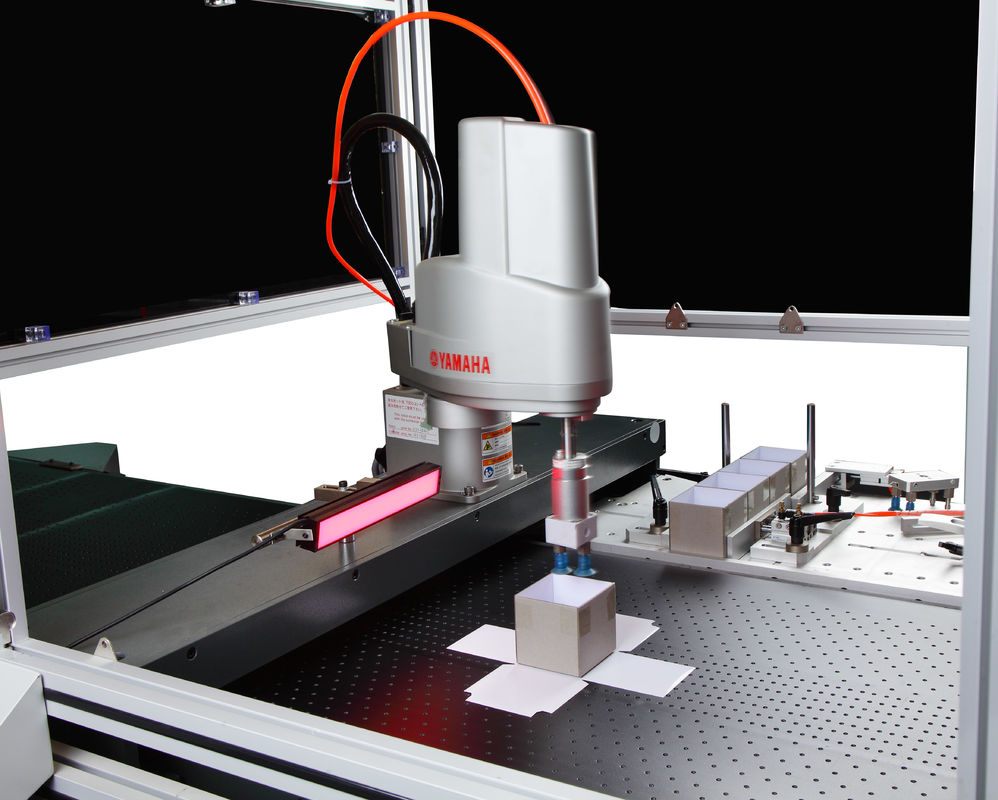

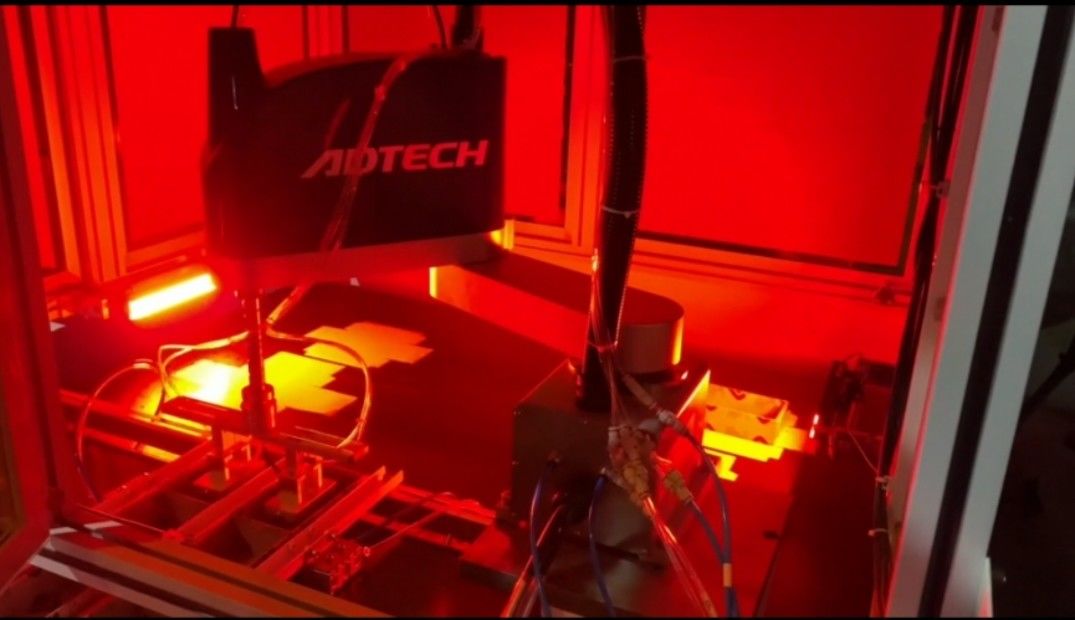

Positioning

1 . SCARA (Selective Compliance YAMAHA Robot Arm) for spotting the grey board box

2. Germany Balser camera with Japan Kowa Lens in 10 million Pixel tracing system

3. Double Camera with XY Spool for positioning.

Product features:

Using two industrial cameras with five mega pixels, and YAMAHA robot arm to position, high positioning accuracy(±0.1mm).

High production rate, rigid box production speed up to 25-35pcs/min; case maker and mounted product speed up to 20-30pcs/min.

Using an independent man-machine control system, transfer machine time is short, fast transfer version.

Feeding stably , does not suck up double sheets easily, reduce product rejection rate.

Independent gluing & positioning module, can be optionally matched with corner pasting machine, splicing board box making machine, pneumatic machine and case maker machine etc to produce of case maker, mounted, rigid box and opening window.It is strong and extensible for the future product

Specification

Packing&Delivery

Our Company

LiShunYuan, founded in 2001, with the aim of developing machines for automating the Rigid Box making process. By 2009 Lishunyuan developed the its first fully automatic line which changed the industry standards. For this innovation the company won the “Excellent Enterprise” & “Best Creativity Award” at the International Industrial Automation Design Seminar.

Over the years, Lishunyuan has a claim to over 200 process patents and over 100 product quality attestations.

The current version of the machine is in its 5th generation

- More than 20000 m2 coverage of manufacturing base

- Machining and R&D advantage

- Machine integrated with world class brand

- Certifications, Patents, Software Copyright

Exhibition